DMarts10

Well-Known Member

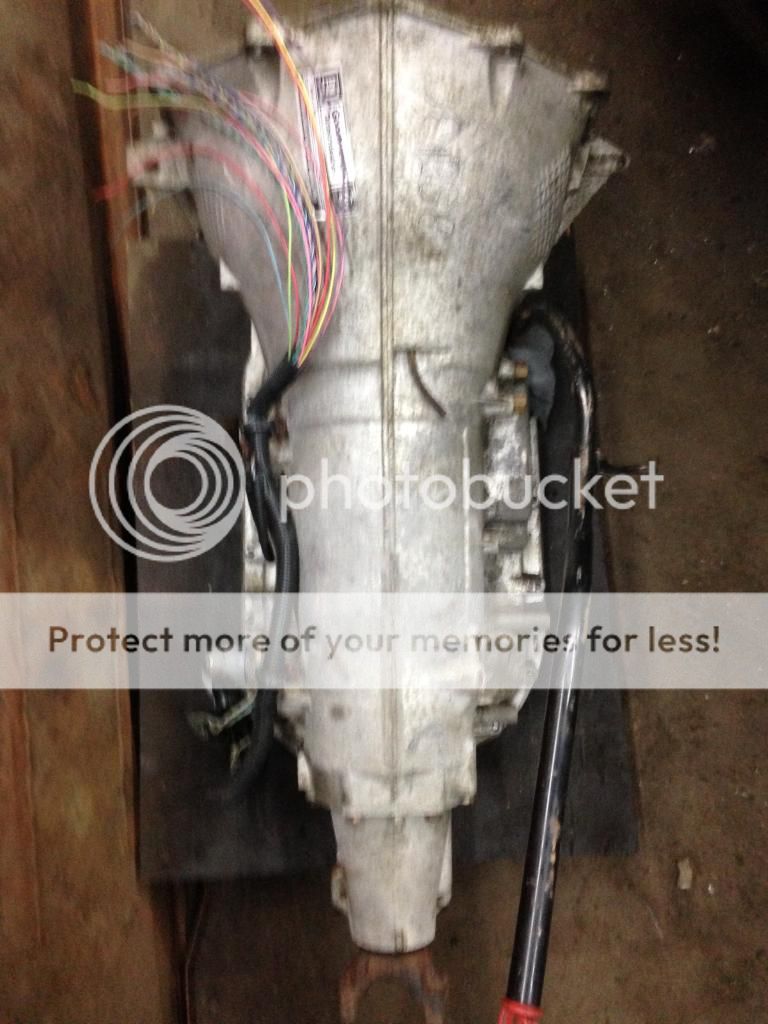

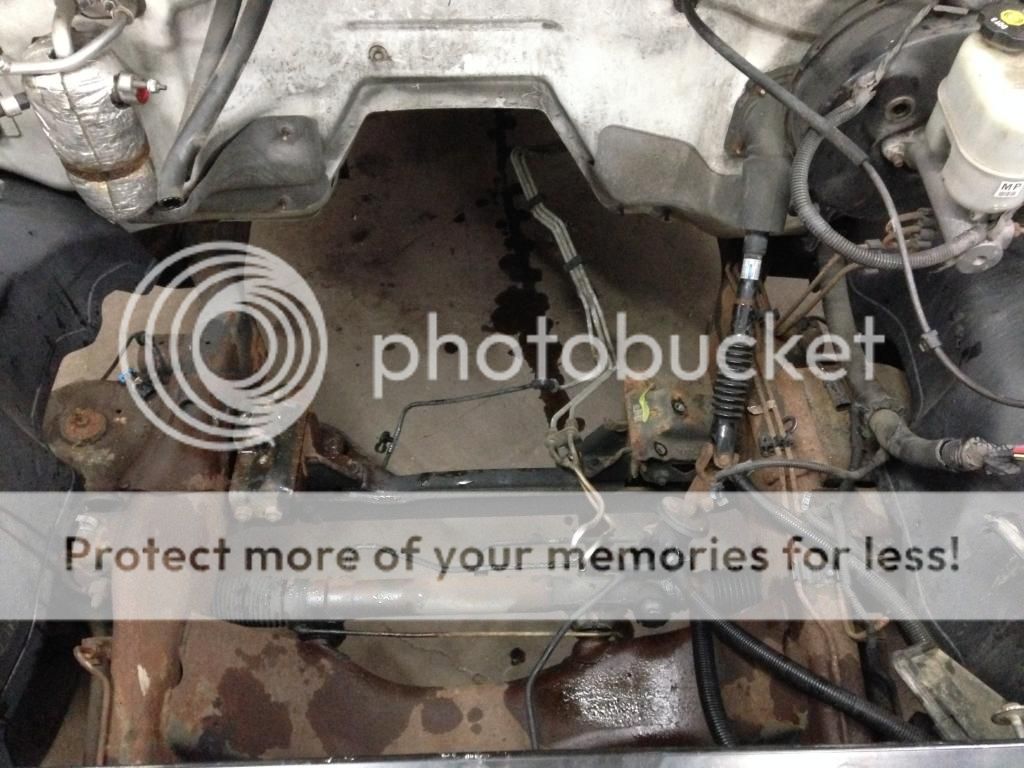

Got a little more work done today (took Monday off to enjoy the holiday at the beach). My plan was to install the valve cover and intake gaskets and bolt them all up, but isoon after realized that I don't have the ls6 intake manifold bolts, and they aren't the same as the truck ones. So I ordered them from ebay for 15 bucks. I got the valve covers done, then cleaned the coils and mounted them to the brackets and to the valve covers, along with routing the wiring. Then I got my oil dipstick sanded and painted, along with the power steering pump, which is still hanging. I pressed on the harmonic balancer/ damper and hooked up all the sensors on the engine block. I had to bend the fuel line out of the way of coil #5 as well. I had to bring my water pump to the machine shop at my bowling alley to press the pulley off it. I will be using an ls1 pump with a truck pulley to get the neck away from the throttle body. Here are the updated pics: